Our office hours:Mo - Fr | 07.30 - 16.00Call us:+49 911 659 680

Bridge Cap Anchor for dynamic loading DB

Bridge Cap Anchor

TOGE TSM BC SB

For new cap construction on DB bridges for dynamic loading

The TOGE TSM BC BS bridge cap anchor with head bolt washer for new cap construction on DB bridges: approved by the German Federal Railway Authority for alternating fatigue loads up to 5 mi. load cycles as defined by DB RIL 804. In combination with injection mortar, it allows high load absorption in cracked and non-cracked concrete. The composite mortar seals the borehole during application, preventing water penetration. This TOGE bridge cap anchor is approved for concrete strength classes from C20/25 to C50/60.

TOGE TSM BC SB Bridge Cap Anchor – At a Glance

Approval

Approval by the German Federal Railway Authority for alternating fatigue loading up to 5 million load cycles as defined by DB RIL 804 for TSM BC SB 22 M24.

Approval

Approved by building authorities as shear-connector.

Force Transmission

Transmission of forces in existing concrete by the undercutting technique in combination with chemical mortar.

Force Transmission

Force transmission in new concrete via shear studs (hexagonal head or shear stud washer).

Impermeability

Verification of the impermeability of the system without or after alternating load.

Headshapes and Materials

Which product is right for you?

Do you need support?

We will be happy to help!

Call us: +49 911 659 68-10

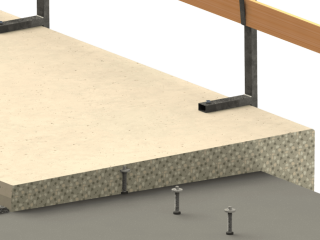

Application Examples

Fastening of new bridge caps

for DB bridges with the TOGE TSM BC SB 22

Detail

Approval | Installation Instructions | Technical Information

Approval

General type approval + General technical approval Z-21.1.1799

General type approval + General technical approval Z-21.8.1880

Federal Railway Authority approval 213.3-213izbia/005-2101#011

Base Material

Application in cracked and non-cracked concrete

of strength classes from C20/25 to C50/60.

This is how simple the installation works:

- Create borehole.

- Thoroughly blow out the borehole.

- Brush the borehole 4x.

- Thoroughly clean the borehole again.

- Discard three full strokes of composite mortar – then inject composite mortar.

- Screw in concrete screw.

- After reaching the screw-in depth, the composite mortar must emerge at the concrete surface. Screw in the head bolt washer to the correct height.