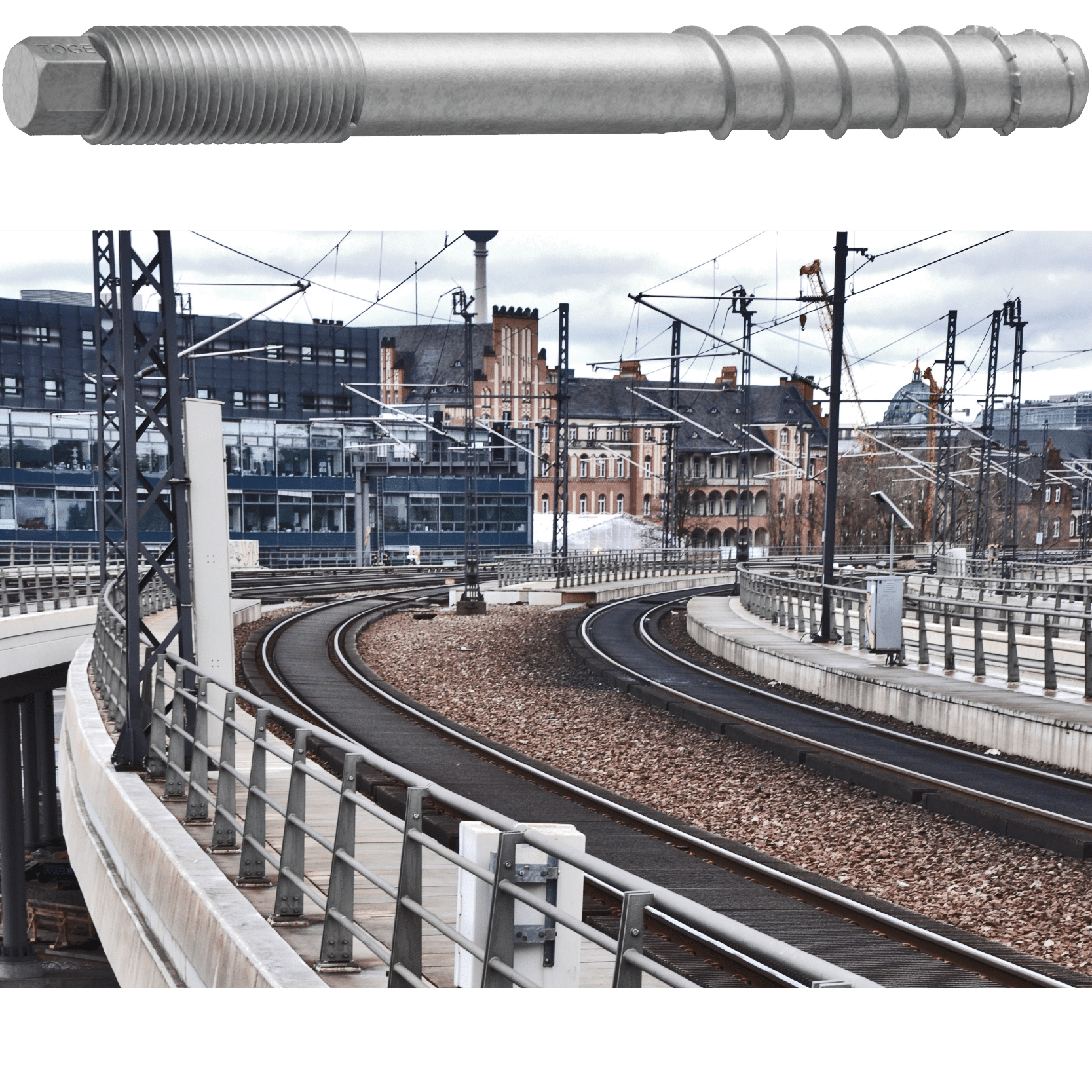

Fastening of Railings + Contact Protection Deutsche Bahn

TOGE TSM BC SB G

Composite anchor screw for fastening railings and contact protection

on structures of DEUTSCHE BAHN

- Authorized Approval

- Low edge distances

- Load Transmission

- Installation

Approval of the Federal Railway Authority for alternating fatigue loading up to 5 million load cycles as defined in DB Ril 804.

Approved for outdoor use with a service life of 50 years.

Low edge distances allow noise barrier uprights to be anchored to narrow components while simultaneously absorbing high forces.

Transfer of fatigue-relevant actions even with installation-related inclination of the anchors up to 3°.

Transmission of transverse forces even when loaded in the lever arm.

Transmission of forces in the existing concrete by the undercutting technique in combination with bonded mortar.

Fast and secure installation.

Headshapes and Materials

Do you need support?

We will be happy to help!

Call us: +49 911 659 68-10

Approvals | Installation instructions | Technical information

Approvals

General design type approval + general technical approval Z-21.1.1799

Federal Railway Authority approval 213.3-213izbia/005-2101#011

Base Materials

Application in cracked and non-cracked concrete

of strength from C20/25 to C50/60.

How easy installation works:

- Drill a hole at right angles to the base plate.

- Thoroughly blow out the drill hole.

- Brush the drill hole 4x.

- Thoroughly clean the drill hole again.

- Discard three full strokes of composite mortar – then inject composite mortar.

- Screw in concrete screw.

- After reaching the screw-in depth, the composite mortar must emerge at the concrete surface.

- Hand-tighten the tensioning nut against the concrete. Screw on adjusting nut and place elastomer washer.

- Position the post.

- Build formwork.

- Shim base plate with suitable mortar (max. shim height 40mm).

- Fill the annular gap between the screw anchor and the hole in the base plate.

- Place the NLX wedge lock washer with the curvature facing downwards and apply the torque.

Application Examples

Fastening of railings and contact protection on structures of the Deutsche Bahn